Why HVAC Companies Should Look beyond Comfort Cooling

The case for tapping into the growing process cooling market

In the crowded HVAC market, finding new revenue streams is critical for businesses looking to grow and differentiate themselves. Yet many firms remain solely focused on comfort cooling, potentially overlooking a parallel business opportunity that builds on their existing skills. In this article, Chris Ferriday from Atlas Copco explores why HVAC companies should consider diversifying into process cooling, an area that can draw on their established expertise while offering access to higher-margin projects, longer-term contracts, and deeper client relationships.

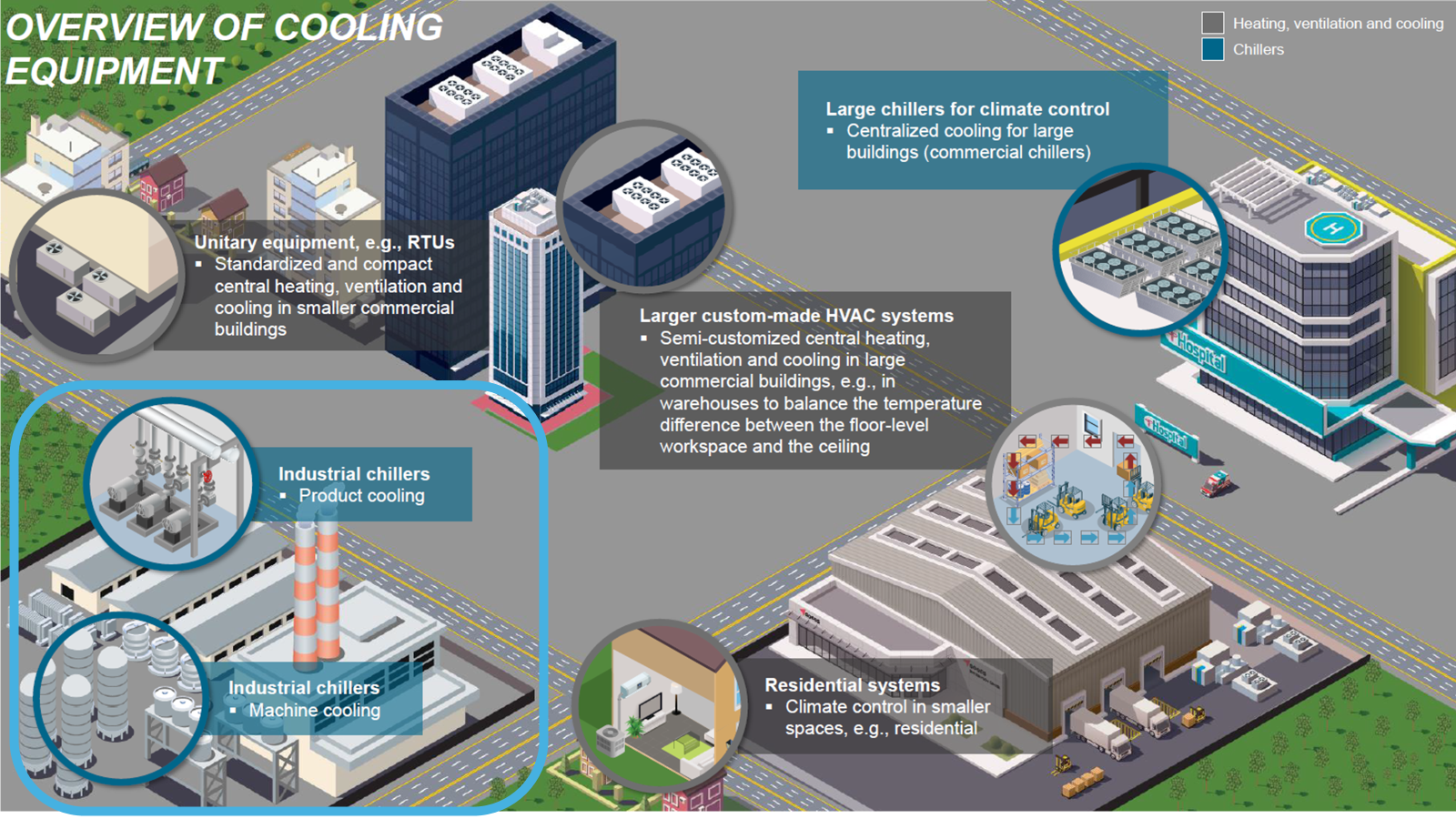

Process cooling refers to the technology used to manage heat generated by industrial processes. It is essential in sectors like manufacturing, food processing, pharmaceuticals, and electronics, where precise temperature control is critical to maintaining product quality and operational efficiency. Unlike traditional HVAC systems, which are primarily designed for human comfort, process cooling solutions are engineered to handle the intense thermal loads generated by production machinery, chemical reactions, and high-speed manufacturing lines. This makes them vital for industries where even minor temperature fluctuations can compromise product quality or disrupt production schedules.

For businesses (and people) that understand the principles of heat exchange, refrigerant circuits, and system diagnostics, this is a logical next step. Many of the core skills required for process cooling – including system commissioning, maintenance, and troubleshooting – are directly transferable from the HVAC sector.

HVAC engineers are already experienced in managing complex, high-value equipment and ensuring it operates efficiently over long periods. This operational expertise is critical in process cooling, where even minor system failures can lead to production downtime or compromised product quality.

Because of the technical overlap, there are compelling commercial reasons to consider this shift. Process cooling systems are often critical to a client’s core operations, making them less susceptible to cost-cutting measures. Unlike comfort cooling projects, which can be highly competitive and price-sensitive, process cooling installations are typically regarded as essential investments, commanding higher margins and offering significant cross-selling potential. For example, a manufacturer might also require ongoing maintenance, system upgrades, and regular efficiency assessments, creating a steady stream of repeat business.

Process cooling systems also tend to have longer lifecycles and more complex technical requirements, enhancing the potential for long-term customer relationships. This is a crucial consideration for HVAC businesses looking to escape the seasonal peaks and troughs of comfort cooling work, where demand can be heavily influenced by weather and economic conditions.

Yet the barriers to entry are often perceived as high. Process cooling systems are more technically demanding, requiring a deeper understanding of thermal dynamics and industrial processes. However, this knowledge gap is often less daunting than it appears, particularly for firms already experienced in larger HVAC installations. Many of the core skills, such as system diagnostics, refrigerant management, and heat transfer calculations, are directly transferable. This technical foundation means HVAC businesses can quickly gain credibility in the process cooling sector, leveraging their existing expertise to secure high-value contracts.

For those willing to make the leap, the rewards can be substantial. Expanding into this sector can open doors to industries as diverse as automotive, food and beverage, plastics, chemicals, and pharmaceuticals.

These sectors rely on precise temperature control to maintain product quality and operational efficiency, creating a constant demand for reliable cooling solutions. This means the potential for larger contracts, more predictable income streams, and higher customer loyalty.

However, success in this market requires more than just technical competence. It demands a shift in mindset, moving from the often transactional nature of comfort cooling projects to a more consultative approach. Industrial clients expect their cooling partners to be deeply familiar with their processes and to offer bespoke solutions that enhance productivity and efficiency. This means becoming a trusted advisor, not just a supplier.

Partnerships with established process cooling specialists can help bridge this gap, providing the trainin/lg, technical support, and brand credibility needed to compete in this more demanding market. This is where firms like Eurochiller, now part of Atlas Copco’s Process Cooling Solutions business line, can be invaluable. Companies such as these offer structured reseller programmes designed to help HVAC businesses expand into process cooling, providing everything from hands-on technical training to service support and ongoing assistance.

For HVAC companies ready to explore this opportunity, partnering with a trusted process cooling specialist can provide the technical support and industry credibility needed to succeed. The path to long-term growth and diversification is clear for those willing to take the first step.

Chris Ferriday

Business Line Manager, Atlas Copco Process Cooling Solutions

Tel: 0800 181 085

Email: chiller.sales@atlascopco.com

Part of Atlas Copco Group | Privacy Portal

.jpg?width=268&height=100&name=Eurochiller_logo%20(1).jpg)

.png)

.jpg?width=161&height=60&name=Eurochiller_logo%20(1).jpg)